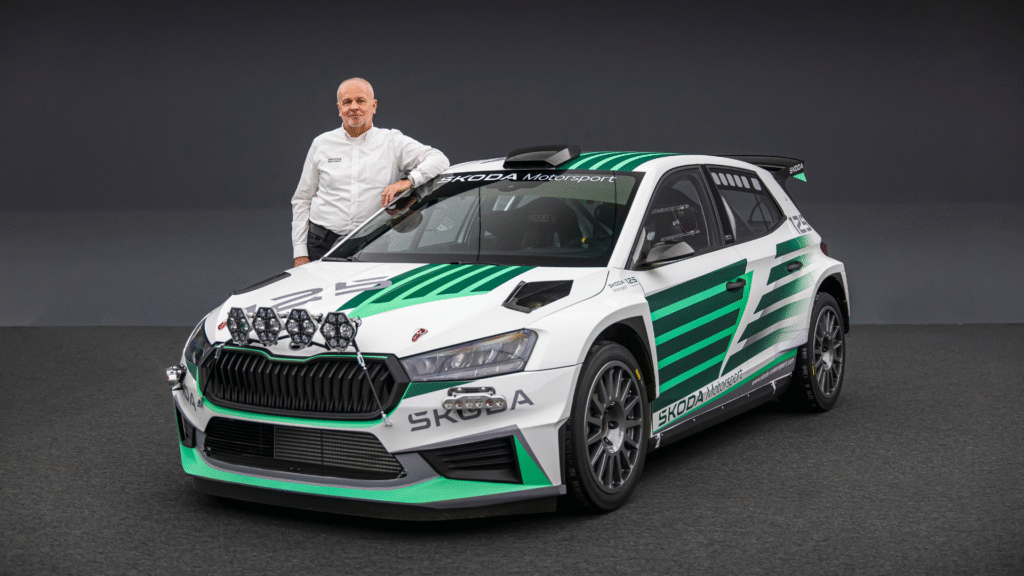

Just like the entire Škoda Auto company, the Škoda Motorsport department is placing increasing emphasis on sustainability across all its activities. This commitment extends to every area – from the development and production of its rally cars to their operation and logistics.

Motorsport as a whole is moving toward greater sustainability, and the activities of Škoda Motorsport are a clear example of this direction. In many aspects, the division goes far beyond what is required by FIA sporting regulations.

One such area is the development of sustainable lubricants for its rally cars. In cooperation with suppliers, Škoda Motorsport has already developed and tested a sustainable engine oil, which is used as the first fill in newly produced customer cars. “A rally engine operates under unique conditions. It requires an oil that maintains its properties even at high temperatures,” explains Jakub Jareš, describing one of the technical challenges.

In addition to the engine oil already in use, the motorsport division is also testing sustainable fluids for shock absorbers, transmissions and differentials. “We are continuously searching for and developing the final specification,” says J. Jareš, adding: “Our testing takes place both in the laboratory and on various surfaces, which enables us to provide valuable feedback to our suppliers.”

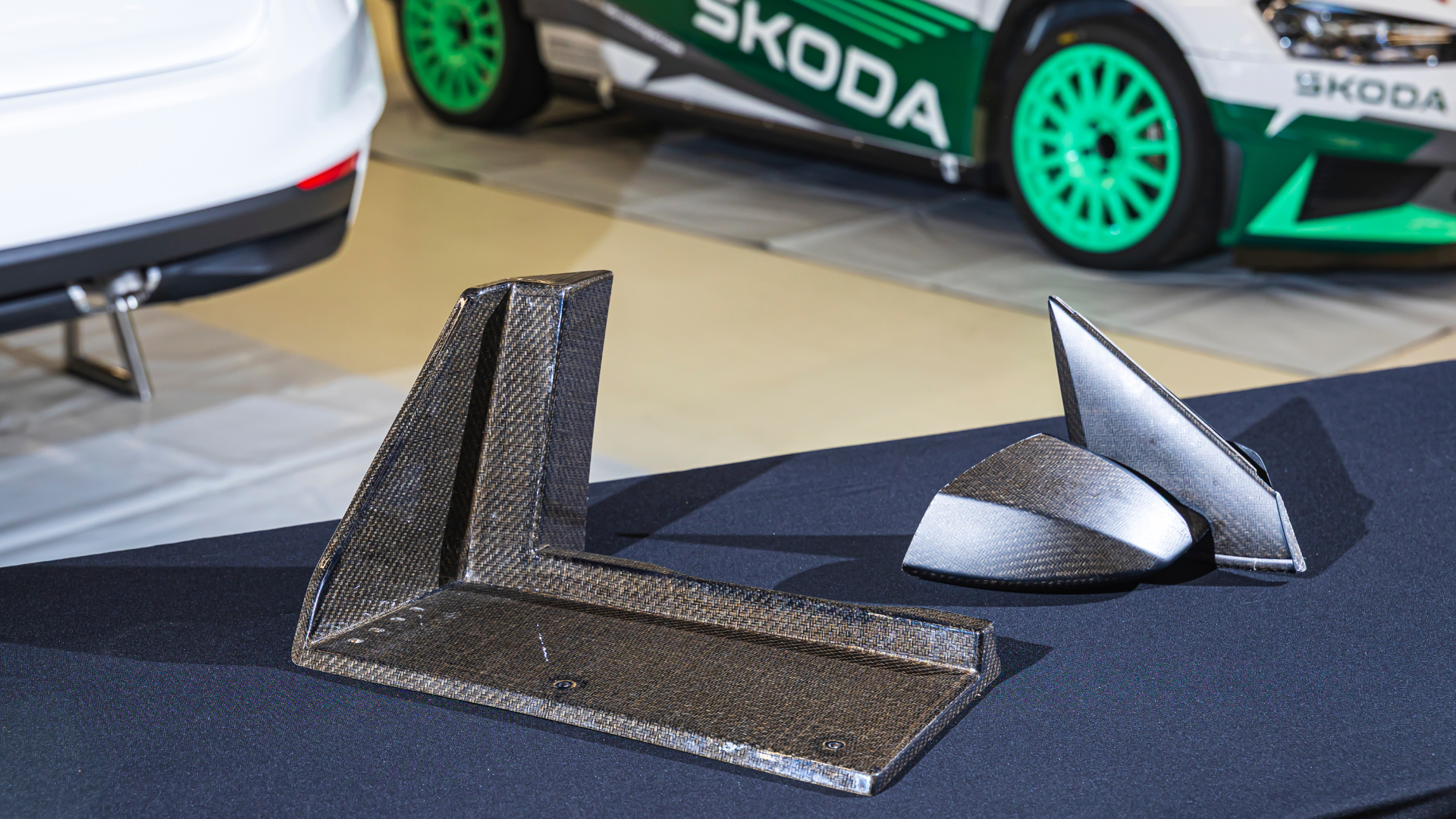

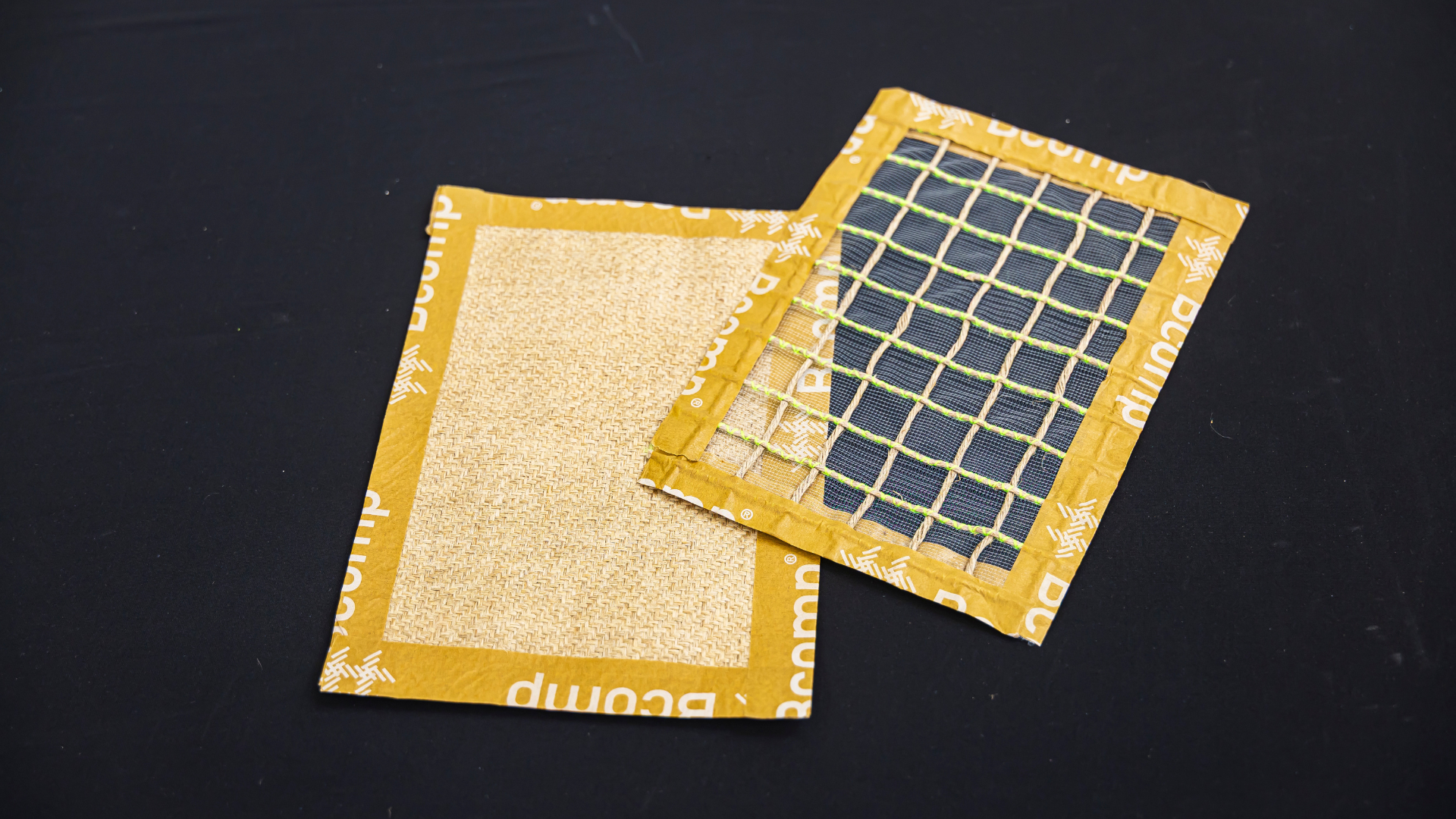

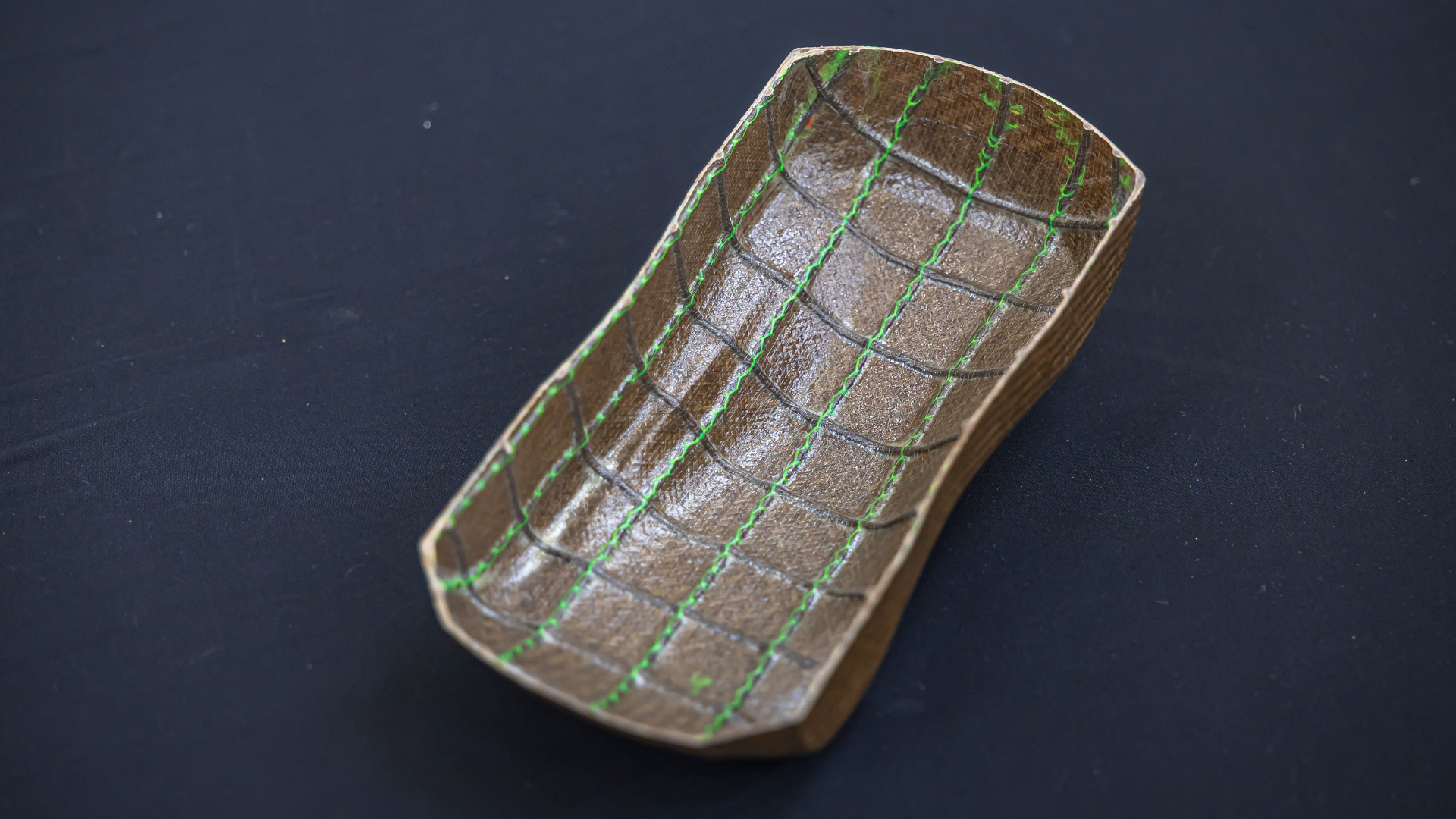

Škoda Motorsport is also working on the use of biocomposite materials. One composite part containing flax fibres is already installed in every produced rally car, and the team is exploring further applications. “These components are manufactured in essentially the same way as conventional carbon parts, meaning they are cured in an autoclave. Their strength and dimensional stability are sufficient for use in a rally car,” notes J. Jareš.

Another sustainable approach is the use of 3D printing. Škoda Motorsport mainly uses this method for prototype parts that would otherwise require a costly and complex preparation of injection moulds. The printed components are also recyclable, and the division is part of a programme that ensures this recycling process. For livery applications, Škoda rally cars now use sustainable films, and in logistics, Škoda Motorsport reduces the use of plastics by switching to recycled packaging materials.

“Apart from our sporting activities, our goal is to be at the forefront of sustainability as well. From an engineering perspective, this presents a major challenge, but as a company, we are keen to take on such challenges,” says Holger Peters, CFO, Member of the Board of Management for Finance, IT, and Legal Affairs, commenting on Škoda Motorsport’s sustainability initiatives.